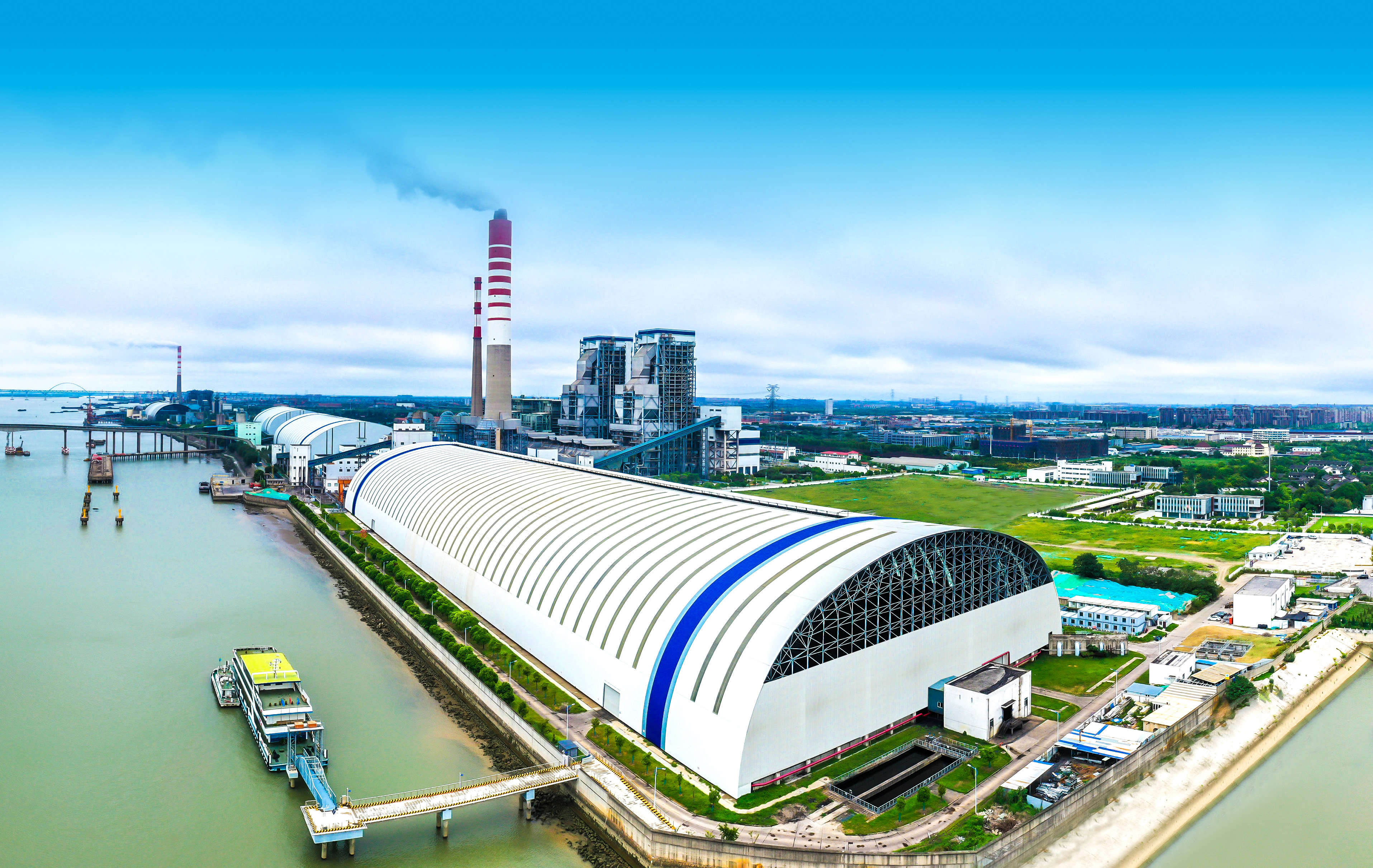

Project Name: Jiangsu Nantong Power Plant

Project Location: Nantong City, Jiangsu Province

Applied Product: Fluorocarbon (PVDF) Pre-painted Steel Sheet

Nantong Power Plant is situated in Tianshenggang Town, Nantong City, Jiangsu Province—a port-industrial city known as “China’s First Modern City.” To the south lies the Yangtze River, and to the north runs National Highway 204, offering convenient transportation suitable for coal delivery and power transmission. The plant is equipped with a 70,000‑tonnage direct coal‑unloading wharf along the Yangtze River shipping route. By the end of 2020, it had cumulatively generated 192.874 billion kWh of electricity, achieving sales revenue of 57.272 billion RMB, thereby contributing significantly to local economic development and enterprise growth. (Source: Power Plant official website)

During operation, factors such as humidity, temperature, corrosive gases, and dust collectively create a particularly demanding environment. For example, the combustion of fuels like coal releases large amounts of corrosive gases such as sulfides, which combine with moisture in the air to form acidic solutions.

Coal ash deposited on steel surfaces can act as an electrolyte, accelerating the electrochemical corrosion of steel structures. Hence, durability remains one of the key challenges in the building envelope system of power plants.

From the customer’s perspective, Tianjin Xinyu thoroughly evaluates various corrosion factors and provides power plant clients with more suitable coated steel solutions, aiming to achieve long‑term corrosion resistance and extend the service life of buildings.

Xinyu Fluorocarbon (PVDF) Coating

This project employs Xinyu Fluorocarbon (PVDF) pre-painted steel coil/sheet. Utilizing advanced coating-surface technology, a uniform fluorocarbon (PVDF) coating containing 70% polyvinylidene fluoride (PVDF) resin is applied over a 55% aluminium-zinc alloy coated steel substrate. This gives the steel outstanding UV resistance, excellent weatherability, and resistance to fading and chalking, while also providing long-term protection against corrosion from acids, alkalis, and organic solvents.

Xinyu 55% Aluminium‑Zinc Alloy Coated Substrate

Beneath the coating lies Xinyu’s 55% aluminium-zinc alloy coated steel substrate. The coating, primarily composed of aluminium, zinc, and silicon with trace elements, solidifies at high temperatures around 600℃, offering high corrosion resistance, high density, and excellent ductility. It meets the requirements of various corrosive environments, withstands the dual tests of time and harsh conditions, and delivers long-term durability.

Even as time passes, Xinyu Fluorocarbon (PVDF) pre-painted steel sheet, with its tough, superior, and reliable performance, builds an enduring barrier for building envelope systems.