From small daily kitchen utensils to large ships, electric power, petrochemicals, stainless steel is widely used in various fields as a variety of functional materials. Compared with traditional carbon steel, the service life of stainless steel is 3 to 5 times that of carbon steel. It has the green properties of corrosion resistance, long life, light weight and recyclability.

The origin of stainless steel

The development of stainless steel began in the late 19th century, when British metallurgist Harry Brearley accidentally discovered during his experiments that adding chromium to steel could improve the steel's corrosion resistance, laying the foundation for the development of stainless steel.

Classification and properties of stainless steel

Stainless steel is mainly divided into four categories: austenite, ferrite, martensite and precipitation hardening stainless steel. Each type of stainless steel has different performance characteristics due to its different composition and production process.

Austenitic stainless steel has good corrosion resistance and processing performance, good comprehensive performance, and can resist corrosion from a variety of media. It is widely used in kitchen utensils, architectural decoration and other fields; ferritic stainless steel has high strength and hardness and is often used in high temperature and high pressure environments; martensitic stainless steel has high strength and hardness due to its high carbon content, and is usually used to manufacture knives, measuring tools, bearings and other parts that require high hardness and wear resistance; precipitation hardened stainless steel, by adding hardening elements to various types of stainless steel, high strength, high toughness, and high corrosion resistance are obtained. It is widely used in cutting-edge fields such as aerospace.

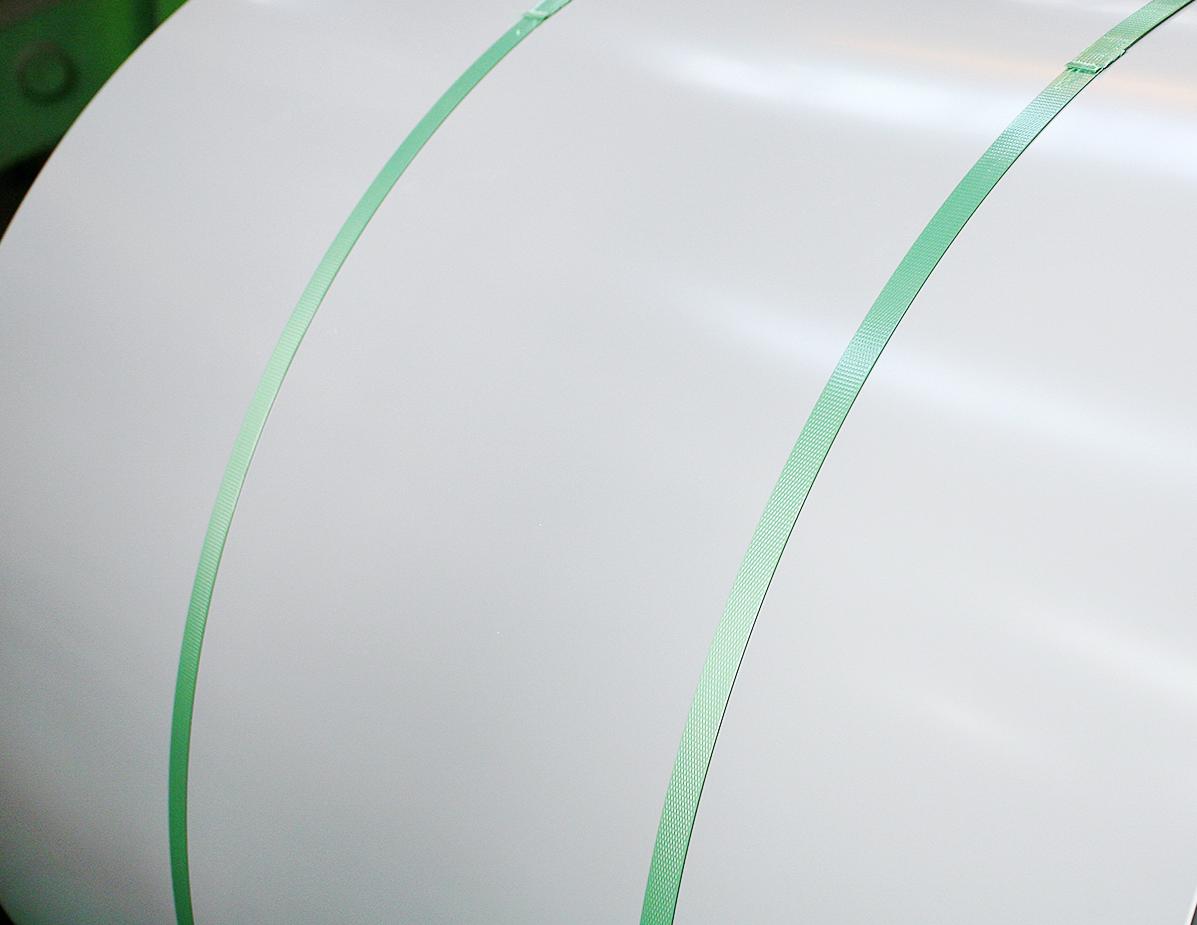

Xinyu stainless steel color coated plate

As a green steel material throughout its life cycle, stainless steel is in line with the national strategy and the direction of low-carbon and high-quality development. As an expert in coating and plating steel plate solutions, Xinyu stainless steel color-coated plates are made of stainless steel as the substrate, which is chemically treated on the surface, colored with paint, and then baked at high temperature.

Product Advantages

High corrosion resistance: Stainless steel itself has good corrosion resistance. After the addition of special reinforced color coating, it can form an anti-corrosion isolation layer, further improving the corrosion resistance of the contact surface with other materials or condensed water.

High strength: Stainless steel color-coated plate has good rigidity and strong resistance to snow load and wind load.

Environmentally friendly: Stainless steel is a recyclable material with a high recycling rate. It does not release toxic gases or substances, has a low metal surface loss rate, and does not pollute the environment.

Economical saving: low maintenance requirements, long life cycle, high cost-effectiveness for long-term use, recyclable and high residual value.

·Aesthetics: Traditional stainless steel plates have strong light reflection and a rather monotonous appearance. Color-coated stainless steel plates can solve light pollution while fully meeting the individual needs of architectural design and improving the aesthetics of the application.

Application Areas

Can be widely used in large public buildings such as airports, stations, stadiums, etc.

Special fields with high demand for corrosion resistance, such as power generation, chemical industry, coastal areas, and solar energy

Stainless steel has the advantages of high corrosion resistance, high strength, long service life, environmental friendliness, and economic savings. Xinyu stainless steel color-coated plates can also be customized in color and texture to break the monotony of stainless steel appearance and fully meet the diverse aesthetic needs of different scenes.